My machine (basically this build: https://www.thingiverse.com/thing:1514145) has GRBL 0.9 : https://github.com/grbl/grbl/wiki/Configuring-Grbl-v0.9The documents for newer version are up there too, obviously. It would definitely be good to get v1.1 working in order to learn the process of getting it on a fresh Arduino board. I'll outline the process of how to do that in the section below this one and fill in the details as I get around to figuring them out. Here's what I do know for sure though...

Sending GCode to the Machine

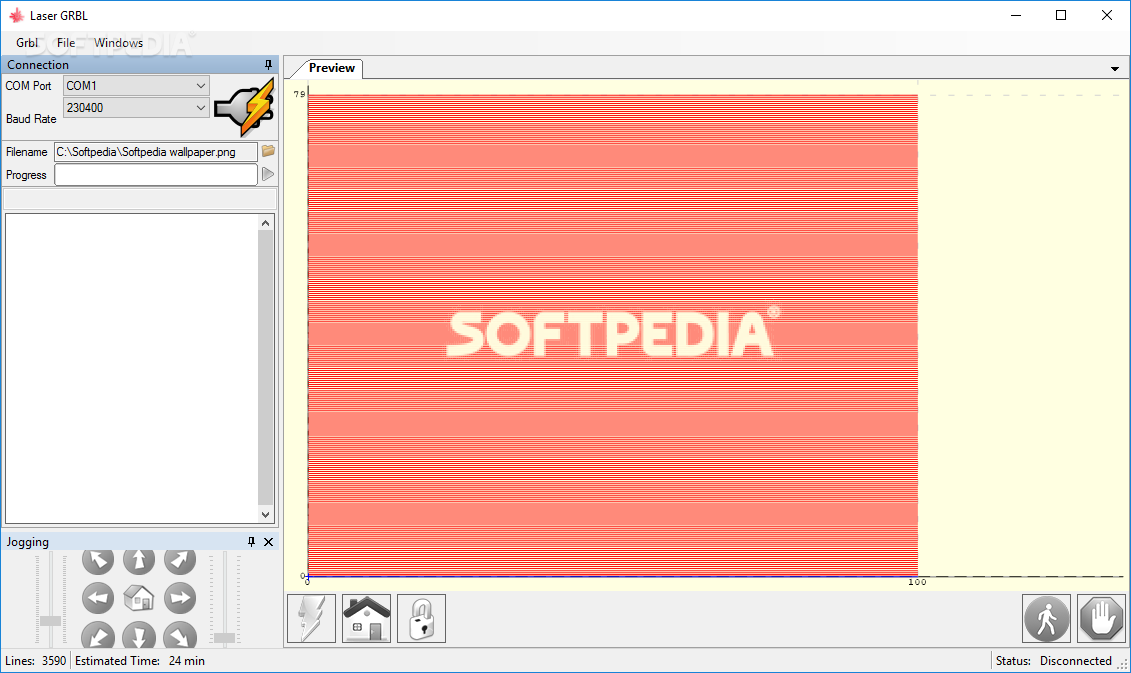

GRBL CONTROLLER. Informatie (ENG): Grbl Controller is software that is designed to send GCode to CNC machines, such as 3D milling machines. It isn’t super smart, it just needs to give the user a nice way to get commands down to whatever controller they are using. Version 3.0 is has been optimized for the Arduino to control Grbl shields. GRBL controller application with G-Code visualizer written in Qt. Supported functions: Controlling GRBL-based cnc-machine via console commands, buttons on form, numpad. Monitoring cnc-machine state. Loading, editing, saving and sending of G-code files to cnc-machine. Visualizing G-code files. System requirements for running 'Candle': Windows. The CNC router software from Mozaik will take you from design to fully developed machine ready G-code with ease. Few of the features from the long list of this software offers are huge pre-defined parts giving you almost all the parts ready for drag-and-drop, intelligent joinery, intelligent algorithms to get optimized nesting, and the ability to control localized nesting.

You can use any number of GUIs but the premise is always the same.Once the firmware is on your board, connect it via USB, power it on, and search in your /dev/ directory for your Arduino (type that into Terminal and start typing 'tty' and then hit Tab until something shows up). If you have the Arduino software, use the drop down menus to identify an address like /dev/ttyusb#### or /dev/wchusbserial####The numbers will be unique to your computer. Take note of these.If you're using the Arduino software, connect to the chip through there and open up the Serial Monitor. You can start sending GCode right there.You can also follow examples on GRBL's github source to see .ino files to upload via the Arduino software that run your GCode.

TO USE PYTHON

Get the dependency that allows python to send and receive information over your USB ports.git clone https://github.com/pyserial/pyserial.gitcd pyserial && python setup.py install

(Alternatively, pip install pyserial)

You might need a driver to make sure your computer can communicate with your Arduino.

Chinese knock-offs sometimes don't play nice with these. Use http://www.wch.cn/download/CH341SER_MAC_ZIP.html for the Nano, for example. Google around until your device is listed in /dev/.

Authentic drivers are found at http://www.ftdichip.com/Drivers/VCP.htm

Copy this to a .py file (source: https://github.com/grbl/grbl/blob/master/doc/script/simple_stream.py )

Name this file streamGcode.py (or whatever)Create a new file named grbl.gcode and put your code in there.Now you can just run python streamGcode.py

You can also get a sense of what is going on in the python file above and stream GCode commands one-by-one through Python using IPython but at that point, I suggest looking up how to send/receive over the Serial port directly through command-line tools.

TODO Use sys package and create an alias so that you can run a gcode file located anywhere on your computer (to run the above, you would have to be in the same directory as the two files). Throw those edits and instructions up in this tutorial, share it with others.

I think this is how they expect the wiring to be by default: https://github.com/grbl/grbl/wiki/Connecting-Grbl

Step 1 - Clone the GRBL directory

git clone https://github.com/grbl/grbl.git

Step 2 - Configure for your hardware.

TODO This is the bulk of the work. Go ahead and open config.h in the /grbl subdirectory and start editing it according to the custom thing you just built. The ports you wired need to be detailed here. I'm not sure what the default configuration is, but it's Cartesian, not CoreXY.

Step 3 - Configure Paths

DO NOTE THAT THE PATHS MAY BE QUITE DIFFERENT ON YOUR MACHINE.

Add all those AVR compilers to your computer's

$PATH.TODO How to find the compilers on your computer. Mine were in/Arduino.app/Contents/Java/hardware/tools/avr/binSo adding them to my path would look likeecho 'export PATH='Arduino.app/Contents/Java/hardware/tools/avr/bin:$PATH' >> ~/.bash_add'(note the colon separating the path)Add $DEVPATH to

.bash_aliasesor.bashrc(LINUX) or.bash_profile(OSX) ... or a new file~/.bash_addwhere we'll temporarily store these since we only need them for this.

There are a few ways to do this, including editing the aforementioned files in the text-editor of your choice.From the command line, this looks likeecho 'export DEVPATH='/dev/tty.usbmodem1411' >> ~/.bash_add

Add

$AVRPATHas well.echo 'export AVRPATH='~/Downloads/Arduino.app/Contents/Java/hardware/tools/avr/bin' >> ~/.bash_addWrap UpRun

source ~/.bash_addto make Terminal aware of where all the software we'll need to use is located.You can add the above code snippet to your~/.bashrcfile (or equivalent) if you plan to recompile in the future, or just run it each time you want to.

Step 4 - Compile GRBL

This creates a hex file that we then need to flash to the Arduino

For ease, we now add $GRBLHEX to our .bashrc file as well.echo 'export GRBLHEX='/Users/Imogen/Packages/grbl-1.1f.20170801/grbl.hex' >> ~/.bash_custom

Once all the paths and configurations are set, runmake cleanmakein the top-level directory of the GRBL version you cloned (a folder named grbl-1.1f.20170801 or something like that ). Running ls now should reveal the grbl.hex file that you're going to flash.Go to https://github.com/grbl/grbl/wiki/Compiling-Grbl if you want details for Windows or more information in general. It has instructions for flashing right from Arduino, as well as telling you where to find some examples.

Step 5 - Flash your ArduinoMy fake Arduino nano wasn't being recognized by my computer.I downloaded http://sparks.gogo.co.nz/assets/_site_/downloads/CH34x_Install_MAC_10_9_AND_ABOVE.zip and installed it.

Then run

- For v1.+ on the Uno:

$AVRPATH/bin/avrdude -C$AVRPATH/etc/avrdude.conf -pm328p -carduino -P$DEVPATH -D -Uflash:w:$GRBLHEX - For v1.+ on the Duemilanove/Nano:

$AVRPATH/bin/avrdude -C$AVRPATH/etc/avrdude.conf -pm328p -carduino -P$DEVPATH -b57600 -D -Uflash:w:$GRBLHEX

_More info, including older versions:https://github.com/grbl/grbl/wiki/Flashing-Grbl-to-an-Arduino

Sainsmart Cnc 3018 Software

General GRBL Usefulnesshttps://github.com/grbl/grbl/wiki/Interfacing-with-Grbl

I think this is how they expect the wiring to be by default: https://github.com/grbl/grbl/wiki/Connecting-Grbl

Writing G codes for manufacturing components from your design can be very time-consuming and may consume a lot of resources from your workforce. CNC router software is basically designed to generate G codes based on your design. You can also expect design optimization for particular manufacturing technique from the software. Following is the list of few of the best picked CNC router software.

Related:

EnRoute

EnRoute is a CAD/CAM sign making and digital finishing software solution. The software is paid software with the basic version offering features for design, toolpathing, 3D surfacing, Nesting, and production. The long list of features include a complete set of 2D CAD and editing tools, interlocking components creator, 3D relief surface cutting, carve into the surface, true shape nesting with 3 nesting engines, nest near obstructions, and save and reuse toolpaths for fast workflow.

CNC Machine

ConstruCAM 3D works with only one unitary data file- click and go. The software provides an interface for most of the standard formats, thus data can be adopted from AutoCad, coreIDRAW, and ADOBE Illustrator. The software has a long list of features including construction aids, editing, layer technique, tool administration, lines, cubic splines and complex pre-defined elements. The software has integrated “Relief” module to convert 2D or .stl file into 3D file.

Mozaik CNC

The CNC router software from Mozaik will take you from design to fully developed machine ready G-code with ease. Few of the features from the long list of this software offers are huge pre-defined parts giving you almost all the parts ready for drag-and-drop, intelligent joinery, intelligent algorithms to get optimized nesting, and the ability to control localized nesting. The software is available with a price tag.

Cnc 3018 Pro Driver Download

LinuxCNC

LinuxCNC is the software designed specifically for Linux platform for controlling CNC operations. The software can be used to drive milling machines, lathes, 3d printers, and laser and plasma cutters. The software accepts G-code as input and drives CNC Machine in response. You can select your preferred GUI from a variety of GUIs. The software supports rigid tapping, cutter compensation, and many other advanced control features. This software is an open source CNC controller.

CAMotics for Mac

Camotics is the CNC router software basically designed for Mac platform users. Camotics is open source software which simulates 3 axis CNC milling or engraving. Being able to simulate is the critical part of creating CNC tool-paths, and programming without simulating is just like cutting without taking measurements. With Camotics you can preview your cutting operation before you actually start the operation. This allows you to improve your design or optimize manufacturing process before the actual manufacturing begins.

Easy CNC for Windows

Easy CNC is the CNC router software basically designed for Windows platform users. Few of the features that this software offer includes full implementation in C++, compiling and loading with Arduino IDE, Doxygen documentation, G-code interpreter, High modularity with object oriented programming, and firmware support for RAMPS 14.

Best CNC Router Software – GRZ CNC Software

GRZ CNC Software is the most popular software in the CNC router software category. The goal of development of this software is getting direct G codes ready for machining from your designs. Meshcam supports almost all the 3D drawing formats, plus it supports reading from a .dwg format to feature designs from drawings. The software also has an automatic toolpath wizard to get you machined workpiece without implementing time and knowledge for the manufacturing process.

How to install CNC Router Software?

Many of the CNC router software listed above offer a setup file, allowing an easy installation of the software. Few of the software in this category are portable, giving you access from anywhere with just one requirement of bootable USB device. CNC router software is basically designed for getting simulation before running actual machining process to get an idea of the performance and let you optimize the process before actually starting the process.

Gbrl Control Software

While some software in this category offers free service for the basic need of getting simulation, the number of features gets limited for the free version. If you are looking for fully featured software with advanced features like automatic G-code generator and optimization, the paid ones are for you. Each software offering some unique feature over others, it’s the question of personal preferences for selecting one of the best software listed here.